In poultry farms and hatcheries, cleaning hatcher baskets and chicken cages is not just a routine hygiene task.It is a critical operation that directly affects biosecurity, animal health, labor cost, and production efficiency.

Why Cleaning Matters

If containers are not cleaned properly, contamination can spread quickly. Poor cleaning creates problems in several key areas of poultry operations.

Disease and Contamination Risks

Unclean containers are a major source of disease in both hatcheries and poultry farms. However, the contamination risks differ between hatcher baskets and plastic chicken cages.

| Container Type | Disease and Contamination Risks |

|---|---|

| Hatcher Baskets | - Hold fluff, feces (meconium), broken egg contents, and blood - These organic residues create ideal conditions for bacteria, fungi, and other pathogens - Newly hatched chicks have weak immune systems and are easily infected |

| Plastic Chicken Cages | - Accumulate manure, feathers, and feed residue during transport and holding - Harbor bacteria such as E. coli, Salmonella, and viruses - Can cause respiratory disease, coccidiosis, and higher mortality if not cleaned regularly - Dirty surfaces increase ammonia buildup, irritating eyes and lungs and lowering bird performance |

Chick and Bird Quality and Welfare

Clean containers directly affect animal welfare and long-term performance, from day-old chicks to adult birds.

| Container Type | Quality and Welfare Impact |

|---|---|

| Hatcher Baskets | - Contaminated baskets can smear chicks with egg contents and droppings - This leads to dirty, weaker chicks that may be culled or perform poorly later in life - A clean basket provides a hygienic first environment, supporting better livability and early growth - Improved chick quality contributes to stronger flock performance downstream |

| Plastic Chicken Cages | - Dirty cages increase stress in chickens during holding and transport - Stress reduces feed intake, egg production, and weight gain - Poor hygiene increases parasite load and footpad dermatitis - Clean cages support better air quality and drier conditions, helping birds maintain stronger immunity |

Farm Performance and Economics

-

Properly cleaned and disinfected containers help maintain high hygiene standards

-

Lower disease pressure reduces treatment costs and mortality losses

-

Cleaning after every use supports consistent hatch results

-

Good hygiene protects the wider egg and poultry production chain from contamination

Equipment Longevity

-

Regular cleaning removes corrosive manure acids that can degrade plastic over time

-

This helps prevent cracks, damage, and early replacement of cages

-

Effective cleaning reduces biofilm formation and simplifies sanitation

Where Cleaning Becomes Difficult

Most cleaning failures do not happen on flat, open surfaces. They happen in corners, joints, tight mesh areas, stacked contact points, and warped plastic. These areas are easy to miss and hard to reach.

Hatcher baskets and plastic chicken cages may look simple, but their design makes cleaning difficult. Grid walls, ribs, and reinforced corners trap protein, shell dust, manure, and other organic waste. Over time, these materials build up in places where water and detergent cannot reach with enough force.

Visual inspection alone is not enough. Areas that look clean can still hold bacteria. Understanding where cleaning fails is the first step to improving results.

In the following sections, we will look more closely at the specific cleaning challenges of hatcher baskets and plastic chicken cages, and why they require different approaches.

Hatcher Basket Cleaning Challenges

Hatcher baskets are used in hatcheries during the final stage of incubation. During this time, they come into contact with many types of organic material, including eggshells, egg white and yolk residue, down feathers and chick droppings. This creates a high risk of contamination.

Fine Structures Trap Organic Residue

One of the biggest cleaning challenges is the fine mesh design. Small holes and narrow gaps help protect chicks, but they also trap dirt easily.

Eggshell fragments, feathers, and organic fluids can stay inside mesh intersections, corners, and under reinforcing ribs. Water spray cannot always reach these areas with enough force.

Protein and Fat Residue Is Difficult to Remove

These materials stick strongly to plastic surfaces. They do not rinse away easily and are resistant to cold water, and short washing time is not enough to remove.

Once protein dries, it becomes even harder to remove. Over time, protein residue can lead to biofilm which is far more difficult to eliminate.

Basket Aging

Over time, plastic surfaces roughen. Micro cracks appear. These hold bacteria even after washing. Manual brushing may remove visible dirt but often misses these pores.

High Hygiene Standards

Hatcheries usually have very strict hygiene requirements. Even small cleaning failures can be a problem, leaving little margin for error.

Chicken Cage Cleaning Challenges

Plastic chicken cages are mainly used for transport and handling. Compared with hatcher baskets, they face much heavier contamination and a higher, uneven soil load.

Heavy Contamination and Organic Waste

Chicken cages are exposed to large amounts of manure, feathers, mud, and feed residue. This type of dirt is thick and can dry quickly, especially in warm conditions. Simple rinsing with a hose is usually insufficient to remove this contamination completely.

Large Size and Heavy Weight

Chicken cages are larger and heavier. Common sizes include, for example, 760 × 570 × 260 mm and 960 × 570 × 300 mm. Each cage weighs about 5–8 kg, which makes manual handling difficult.

Hard-to-Reach Structures

Load-bearing parts, corner joints, bottom edges, and stacking points often collect dirt. These areas are difficult to clean with a standard hose or handheld pressure washer.

Labor Pressure and Throughput Limits

In many poultry operations, cleaning chicken cages manually becomes a bottleneck. As cage numbers increase, farms must choose between spending more labor hours or accepting lower and inconsistent hygiene results. Neither option is sustainable in the long term.

Why Manual Cleaning Fails

Many farms still rely on manual cleaning using hoses or pressure washers. This is understandable. The initial cost is low, and the process looks simple.

However, while manual cleaning may work on a small scale, it becomes unreliable in large-scale operations.

Manual cleaning has several clear limitations:

- Inconsistent results

Cleaning quality depends on the operator. Different workers clean in different ways, and results change from shift to shift. - Focus on visible dirt

Workers usually focus on visible dirt. Time pressure pushes speed over detail. Hidden areas often receive less attention. - Limited contact time with detergents

Detergents do not stay on the surface long enough to break down protein and fat residues. - Poor access to hidden areas

Hoses and handheld pressure washers cannot effectively reach corners, joints, and other hard-to-clean spots.. - High labor cost and physical strain

Cleaning large and heavy cages with high-pressure water is hard physical work. Fatigue reduces cleaning quality over time. This is not a lack of effort, but a limit of the method. - Unstable washing conditions

Water pressure changes. Water temperature changes. Workers change. Time pressure changes. All these factors affect the final result. - Increased water and chemical use

To compensate for weak cleaning action, farms often increase detergent concentration.This increases operating cost and puts extra load on wastewater treatment systems. - Lack of Process Data

Manual systems do not record time, temperature, or chemical use. When audit issues appear,root causes stay unclear.

As an engineer, I see farms add more labor to fix this. Costs rise but results do not. Manual cleaning has a ceiling. Once volume grows, failure becomes hard to avoid.

What Effective Cleaning Requires

Effective cleaning is not just about water pressure. It requires a controlled process that combines mechanical action, temperature, detergent, and repeatability.

-

Mechanical action

Proper spray angles and sufficient impact are required to reach corners, joints, and mesh structures. -

Temperature control

Warm or hot water is important. It helps break down protein and fat. Manure is also easier to remove with warm water. -

Sufficient contact time

Detergent needs time to work. It must be used at the right concentration and stay on the surface long enough. Short washing time reduces cleaning effect. -

Consistency

Every container must be cleaned in the same way. The result should not depend on the operator or the load size. Each wash cycle should meet the same cleaning standard.

Why Farms Choose Automated Washing

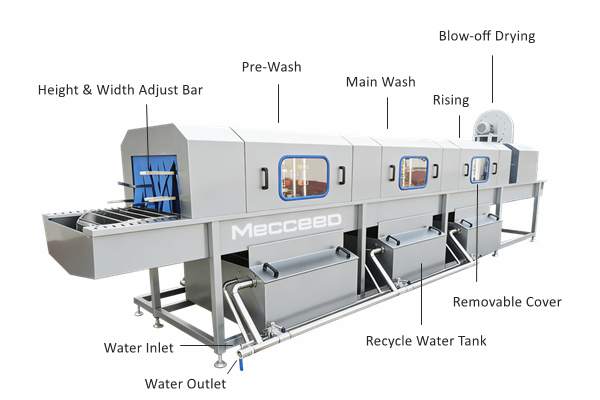

To address these challenges, many poultry farms and hatcheries are moving toward automated crate and cage washing systems. This is not about automation for its own sake. It is about control.

Automated washing systems offer:

-

Controlled water temperature

The washing temperature can be set on the machine. This helps maintain an optimal temperature for cleaning. -

Optimized spray patterns

The system uses adjustable spray nozzles. The spray angle can be set to reach corners, joints, and other hard-to-access areas. -

Repeatable cycle time

Every container is washed for the same amount of time, without shortcuts or variation.

Practical Benefits:

-

Stable and repeatable cleaning results

-

Lower labor dependency

-

Better control of water and chemical usage

-

Improved biosecurity

-

Easier daily management

Automated systems do not replace farm staff. They support them by removing heavy, repetitive work and allowing teams to focus on more valuable tasks.

One System for Different Containers

Although hatcher baskets and chicken cages have different problems, many farms prefer one cleaning system for both.This helps reduce cost and simplify daily operations.

To clean both products effectively, the system must be flexible.

Key requirements include:

-

Flexible settings for sizes

-

Adjustable spray angles

-

Controlled water pressure

Without this flexibility, farms may need separate cleaning equipment.

Matching Washing to Farm Conditions

When selecting or configuring a washing machine, several practical factors should be considered:

- Number of baskets and cages per day

This defines required capacity and throughput. - Available space

Space limits affect system layout and installation. - Water and energy supply

Available utilities determine heating options and washing performance. - Required hygiene level

Higher hygiene standards require tighter process control - Integration with existing workflow

The washing process should fit smoothly into daily operations.

Cleaning Tips

A summary of practical cleaning tips is provided below for quick reference.

- Wash containers soon after every use.

- Allow enough washing time for full contact

- Use hot water for cleaning, but higher temperature is not always better. For hatcher baskets, washing water is usually kept between 40–60°C to avoid protein residues hardening on the surface.

- Use an alkaline, low-foaming detergent

- Follow washing with disinfection using a broad-spectrum disinfectant suitable for poultry operations.

- Let containers dry completely before reuse or stacking.

- Monitor hygiene results regularly using simple surface tests, such as swab tests or contact plates.

Conclusion

In poultry operations, cleaning hatcher baskets and plastic chicken cages is a daily challenge. As a crate washer manufacturer, we work closely with our clients to address these cleaning issues.

If you are struggling with inconsistent cleaning results, high labor costs, or rising hygiene requirements, our technical team is available to discuss washing solutions based on your specific cleaning needs.