Sausages are a convenient and tasty food that many people enjoy. Have you ever wondered how they are made? What steps do they go through in a factory before reaching your table? In this article, we will walk through the sausage processing process step by step.

What Is the History of Sausage?

The word “sausage” comes from the Latin word salsicia, which means “seasoned with salt.” Sausages first appeared more than 5,000 years ago, around 3,100 BCE, in ancient Mesopotamia. The exact inventor is unknown.

Sausages developed because people needed a way to store meat for longer periods. Before refrigeration, fresh meat spoiled quickly. By cutting meat into small pieces, adding salt, and stuffing it into animal intestines, people could slow spoilage and reduce waste. Smoking added heat and natural chemicals that helped protect the meat.

Ancient records show sausages in many regions, including China, Greece, Rome, and the Middle East. Each area used local animals and spices, but the basic idea stayed the same. Meat, fat, salt, and a casing formed the core structure.

Over time, the tools changed. Knives became grinders. Hand mixing became mechanical mixing. Open fires became controlled smokehouses. Today, sausages are still made using the same basic principles, but modern machines make the process safer, more stable, and easier to repeat.

What Animals Are Used to Make Sausage?

Different animals are used to make sausages. Pork is the most common. Beef, chicken, turkey, and lamb are also used. Some sausages use a mix of meats.

The main ingredient is meat, but sausage is not 100% meat. Fat is needed for texture and flavor. Water or ice is added to control temperature and help protein extraction. Salt and spices add flavor and improve stability.

Some products use binders such as starch or soy protein to improve yield and structure. In some recipes, eggs or milk are added for a smoother texture.

What Is the Sausage Processing Flow?

Sausage production follows a strict order. Skipping or changing steps creates quality and safety risks. The main steps are ingredient selection, grinding, mixing, filling, cooking or smoking and packing.

-

Ingredient Selection

Meat is chosen and trimmed to the right lean-to-fat ratio. Lean meat provides protein. Fat adds flavor and texture. Meat is often partially frozen to make grinding easier. -

Grinding

Meat and fat are ground to a specific size. The grind size depends on the sausage type. Fine grinding is used for products like hot dogs. Coarse grinding is used for products like bratwurst. Grinding increases surface area and prepares the meat for mixing. -

Mixing and Flavoring

Ground meat is mixed with salt, spices, and other ingredients. Mixing creates a sticky matrix. This step forms the binding structure. Flavoring is done here. Even mixing is important for taste and texture. -

Filling

The meat mixture is pushed into natural or synthetic casings. -

Thermal Treatment

Heat is applied to set structure and reduce bacteria. Heat treatment may include cooking or smoking. Cooking uses water or steam. Smoking adds flavor and color. Time and temperature must be controlled. -

Cooling

Quickly lower the temperature to stabilize the sausage structure and prevent bacterial growth. -

Packing

Finished sausages are packed to protect them from oxygen and contamination. Common methods include vacuum packing or modified atmosphere packing. Proper packing helps extend shelf life.

What Equipment Is Used to Process Sausages?

Sausage production relies on a series of specialized machines. Each piece of equipment supports a specific step and helps control quality, safety, and efficiency.

-

Meat Grinder

Reduce meat size and expose proteins. Plate size controls texture. -

Meat Mixer

Combine meat, fat, salt, spices, and water. This step is critical because protein extraction affects binding. -

Meat Filler

Push the mixture into casings. Vacuum filling is recommended to remove air and reduce holes and spoilage. -

Heat Treatment Equipment

Applies controlled heat to set structure and reduce bacteria, such as cooking machine or smoking machine. -

Cooling Equipment

Rapidly chill sausages after heat treatment. -

Packing Machine

Seals finished sausages in vacuum or modified atmosphere packaging. This step limits oxygen exposure and reduces contamination risk.

In addition to these main machines, some production lines may also use auxiliary equipment such as clipping machines, hanging systems or peeling machines depending on sausage type and casing choice.

What Food Safety Rules Matter in Sausage Processing?

Sausage production involves biological risks, so hygiene and control are essential at every step. Following proper safety rules helps prevent contamination and ensures consistent, high-quality products.

- Control Raw Materials

Keep meat cold and inspect quality。 - Maintain Equipment Hygiene

Clean and sanitize all machines and tools after use - Prevent Cross Contamination

Keep raw and cooked products separate - Ensure Worker Hygiene

Workers must wear protective clothing and wash hands - Monitor Bacterial Risks

Control bacteria that survive cold or low-oxygen conditions, like Listeria and Clostridium. - Limits of Heat Treatment

Cooking and smoking reduce bacteria but cannot eliminate spores. - Cooling and Storage

Cool products quickly after heat treatment and maintain proper cold storage. - Engineering Controls

Design equipment for easy cleaning and monitor processes to reduce human error and safety risks.

What Types of Sausages Are There?

Sausages are made in different ways and can be classified by how they are processed. Common categories include fresh, cooked, smoked, and fermented sausages.

-

Fresh sausages are not cooked or cured and must be kept cold until cooking.

-

Cooked sausages, such as hot dogs, are heat treated during production.

-

Smoked sausages are treated with smoke and heat for flavor and preservation.

-

Fermented sausages rely on bacterial fermentation to lower pH and develop flavor.

What Types of Casings Are Used for Sausages?

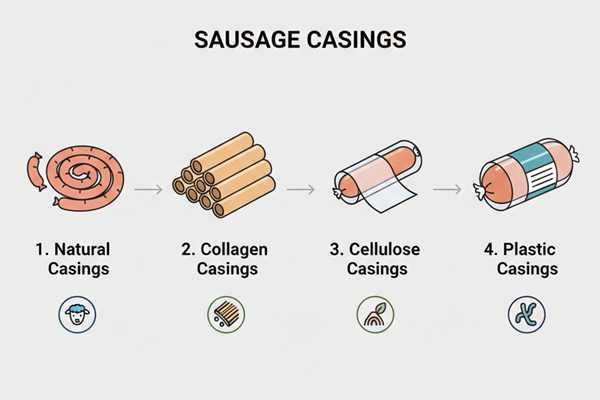

Casings shape the sausage and affect texture. They can be natural or artificial.

Main casing types include natural casings, collagen casings, cellulose casings, and plastic casings.

-

Natural casings come from animal intestines, usually pork or sheep. They have good bite and allow smoke penetration. They vary in size and strength.

-

Collagen casings are made from animal collagen. They offer uniform size and are easier to handle. Some are edible. Some are not.

-

Cellulose casings are plant-based. They are strong and uniform. They are often used for hot dogs and peeled after cooking.

-

Plastic casings are non-edible. They are used for large diameter products. They do not allow smoke penetration unless perforated.

Common Sausages and Their Basic Processing Methods

-

Salami

Made from ground meat(usually pork) and fat with salt and spices. The mixture is stuffed into casings, fermented, and then dried 4-10 weeks at controlled humidity. -

Pepperoni

Made from beef or pork with spices. The sausage is fermented, smoked, and dried. It is a type of dry sausage. -

Chorizo (Spanish Sausage)

Made mainly from pork and paprika. The sausage is cured and smoked or dried. Some types are ready to eat, while others need cooking. -

Hot Dog

Made from finely ground meat. The mixture is processed into a smooth paste, filled into casings, cooked or smoked, and then peeled. -

Frankfurter

Made from pork or mixed meat. The sausage is cured, smoked, and cooked. It is ready to eat. -

Italian Sausage

Made from coarse ground pork with spices like fennel, garlic, and salt. It is a fresh sausage and must be cooked before eating. -

Kielbasa

Made from pork or mixed meat. The sausage is cured, smoked, and cooked before eating. -

Bratwurst

Made from coarse ground pork, beef, or veal. Typically seasoned with nutmeg, ginger white pepper, and marjoram. The sausage is not cured or smoked. It is a fresh sausage and must be cooked before eating. -

Lap Cheong (Chinese Sausage)

Made from pork, fat, sugar, and soy sauce. The sausage is stuffed and dried. Cooking is done before eating.

Conclusion

Sausage production in a factory is a controlled process built on raw material quality, defined processing steps, suitable equipment, and strict hygiene rules. Stable production depends on correct process design and reliable machinery. For more information, please contact us at [email protected]. We are happy to provide customized sausage processing solutions for your needs.